Patrick- I don't know how you got the eCabs output to work on the shopbot, but that is quite an accomplishment because the Rolling Nest on the controller does a lot of the work. When you get into the 3D and small stuff you can only move that head so fast. On the intricate cuts the Shopbot (Original PRT) is every bit as fast as the Thermwood. We use the Shopbot for the intricate jobs and the Thermwood for most of the cabinet work. I have both the Shopbot and the Thermwood machines in the shop and the eCabs software works very nicley linked to the CNC machine. One shop was using MicroVellum w/autocad and like it, but it, too is a pricey alternative. When I was back at the Thermwood factory there were a couple shops in the class that had also dumped CabinetVision for ecabs. I've bumped into a couple of shops now that have dumped CabinetVision. We purchased Cabinetvision a year or so ago and no longer use.

I really don't know which direction to point you.

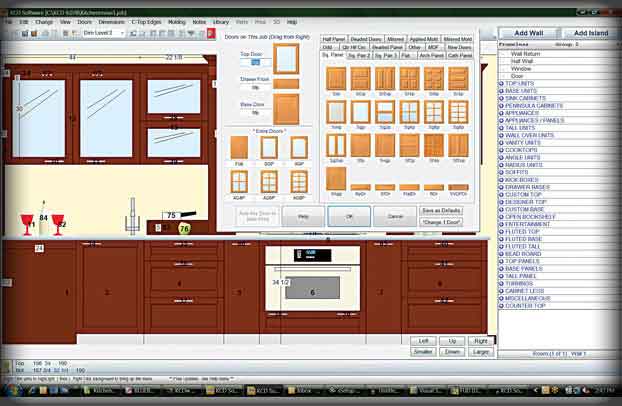

Based on response from this thread I may make a new post showing details of how it works and some screenshots to see if there is enough interest out there.

Kcdw software version 9 for sale how to#

If there are a couple of dozen people willing to spend maybe $200 for something like this it would be worth me polishing it up and throwing it out there along with documentation on how to edit the XML files for customization. But it has only been used for my construction techniques so far and is not polished at all. The product is backed by free technical support and training. KCD Touch is available by subscription for 19.95 per month if you own KCD Software Version 9.

Kcdw software version 9 for sale full#

It is fully configurable by altering some XML files to allow for different styles of construction, etc. The software works on a full Windows 8 or Windows 8 Pro tablet with an i3 or above processor. It optimizes them onto as few sheets as possible and then generates the G Code for each page along with printed diagrams of the sheet layout and sheets of part labels to match. It then generates the parts, calculates dados, rabbets, shelf holes, etc. You can also add individual parts like panels and specify cutouts in any part. You can edit the cabinet properties, give them names, etc. My software basically takes a list of cabinets from eCabinet Systems (could be tweaked to take lists from any software) or you can just add them in one by one. I have been tempted to sell the software for some reasonable price but I don't know if there is enough demand to warrant it. I have cut parts for many hundreds of cabinets with it since then, tweaking it and adding features as needed. In the meantime I also changed to an Ascension controller so I now generate G-Code instead of ShopBot code but I could re-write the output back to SBP I suppose. I have since switched to eCabinets from Thermwood and altered my importer to take their output. A little over a year ago I wrote a program that took the cabinet lists from Cabinet Vision and generated SBP code.

0 kommentar(er)

0 kommentar(er)